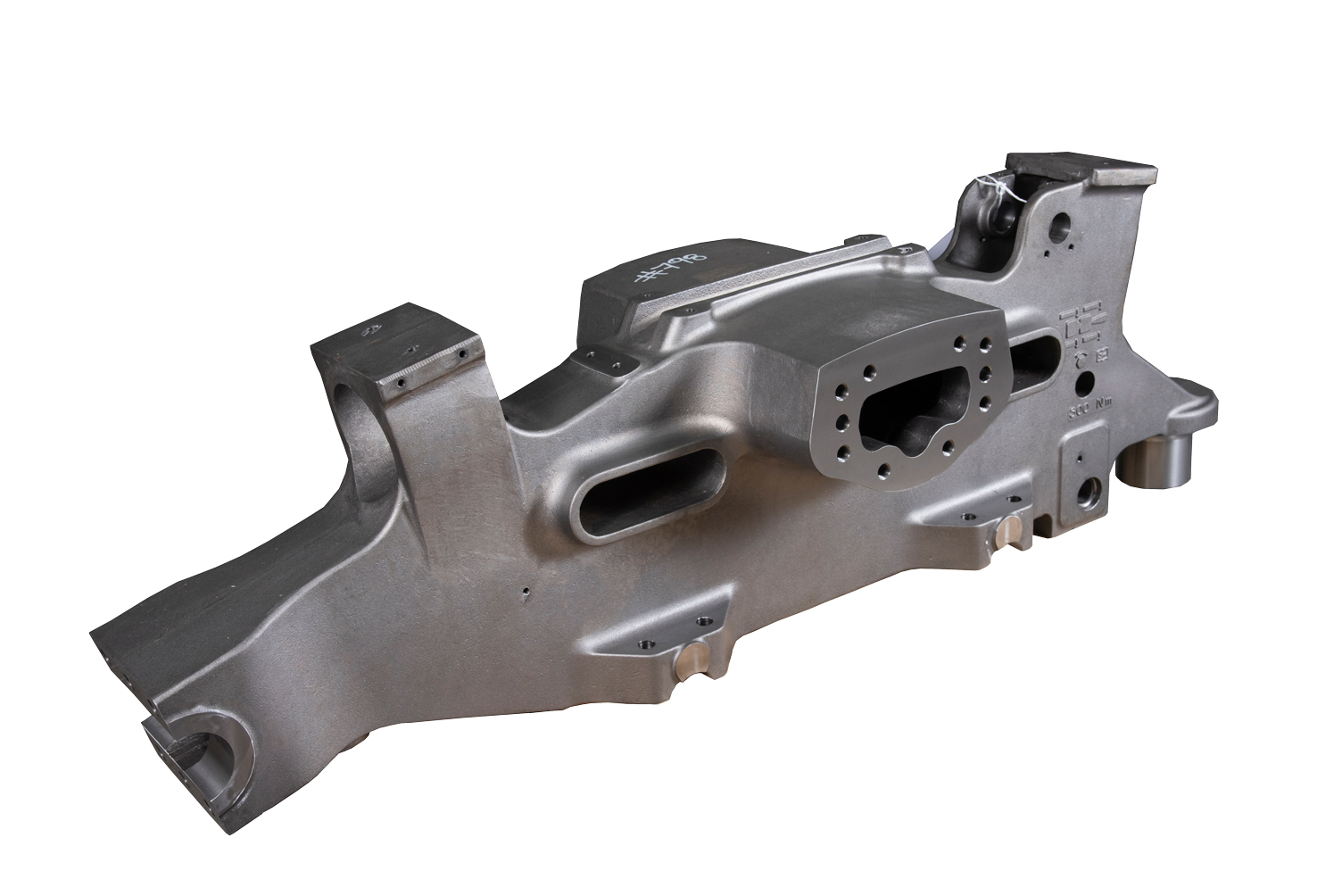

Cast Iron Products and Services

Fast, well done and at the best price

The standard of our processes, the strict control of raw materials and the constant personnel training makes the fabrication of the castings be done with quality, on time and with the best use of resources.

We specialize in:

- Gray iron casting pieces

- Ductile iron casting pieces

- Pattern manufacturing

- Own machining through our partner company Kanoff

Our services guarantee the best product in the shortest time lapse

Different services and a great experience in the same place combine to take the best products to our clients.

- Pattern

“A great casting starts with good pattern”

The pattern is one of the most important elements for casting manufacturing. We count on an area dedicated to design, fabrication, and maintenance that takes care of every single pattern used at FA Foundry to comply with the specifications of the design.

- Machining

We enrich our services and offer a high precision machining process through our partner company Kanoff Machining, located in the same industrial complex. This competitive advantage helps us reduce time during our processes, operative improvements, and product reliability.

- Applied engineering services

- Use of CAD and CAM technology

- Molding simulation software, metal flow, and solidification

- Additional services

- Heat treatment

- Painting

- Anti-corrosion coating

Metallographic laboratory

- Chemical analysis with spectrometer

- Tensile Strength

- Metallographic

Nondestructive testing services

- Hardness

- Ultrasound Testing – Soundness test

- Wall thickness measurement

- Die penetrate liquid

- Borescope – inside of casting visual inspection

- Hydrostatic testing

- Magnetic particles test

Sand laboratory

- Granulometric analysis

- LOI

- Permeability

- Tensile Strength

- pH

- ADV

- Mold hardness

- Density and dry film thickness of refractory pain

For Anticorrosive Coating

- Dry film test

- Adherence